Flexible solutions for every surface.

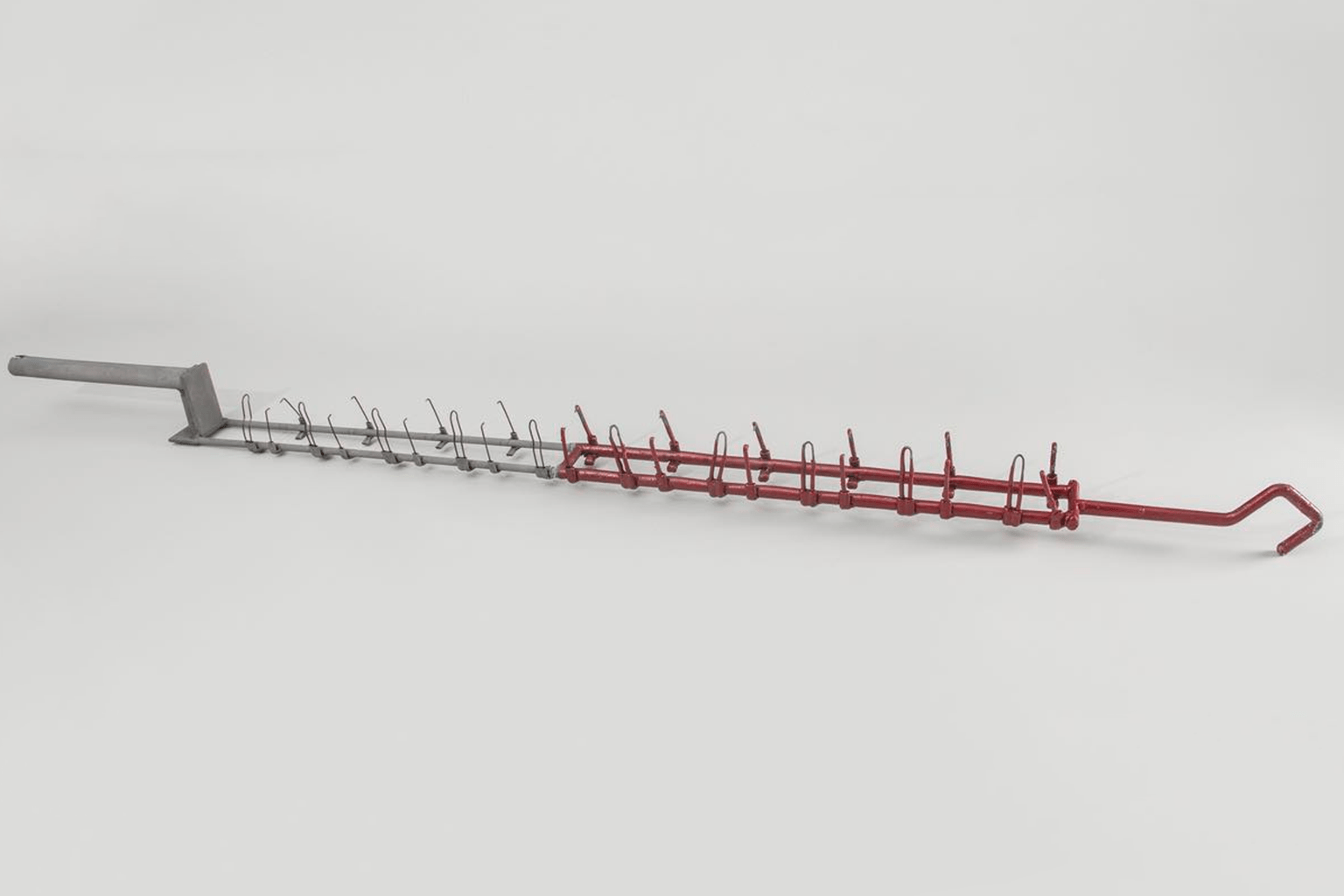

Chemical paint stripping is particularly efficient for devices (jigs, hooks, rims, etc.) or temperature-sensitive parts with paint defects. The stripped parts are rinsed with pressurized water and, if necessary, preserved by passivation.

Cleaned devices or poorly painted parts can be returned to the painting process after paint stripping.

What can we strip?

We clean your devices or flawed painted parts in immersion processes; we can remove paint from a wide variety of metals (aluminum, steel, stainless steel, galvanized steel, etc.) or plastics by using different chemical products.

Our environmental care

In addition to our high-quality standards, we also ensure environmental care. The water used in the process is neutralized and, if possible, returned to the process. Chemicals are neutralized or adequately confined.

We care for the process.

Through constant monitoring and continuous improvement of our chemical processes, we find the optimum solution for different requirements.

Chemical paint stripping is carried out at predetermined CPU-controlled temperatures to ensure the efficiency of the process. Different finishing and passivation treatments can then be applied.